Fluidmanagement

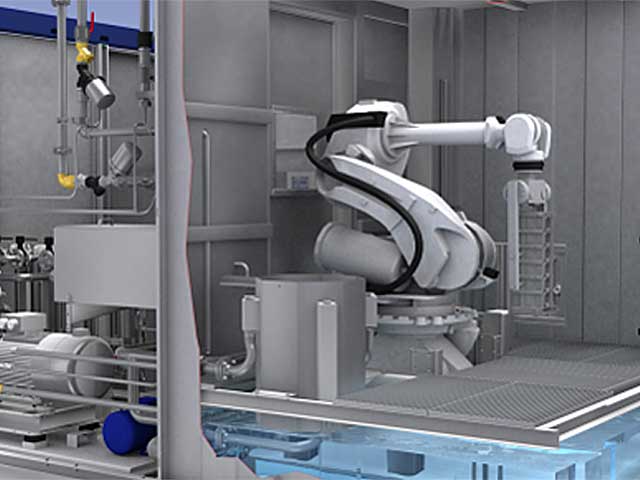

Having an overall view of the planning and the production of parts in a machining line to delivery of the parts into an assembly process is important for value-adding within the whole process chain.

The technologies of coolant management, low volume lubricants and the technical cleaning of parts have to be optimally coordinated.

Coolants and lubricants

Consulting and support for all planning and optimisation tasks in all processes before, during and after production. Which coolant technologies are possible for you and which are the optimum solutions for your processes?

My services will take into account all of your processes.

- Tribology – requirements for optimum tool life and therefore minimal tooling costs.

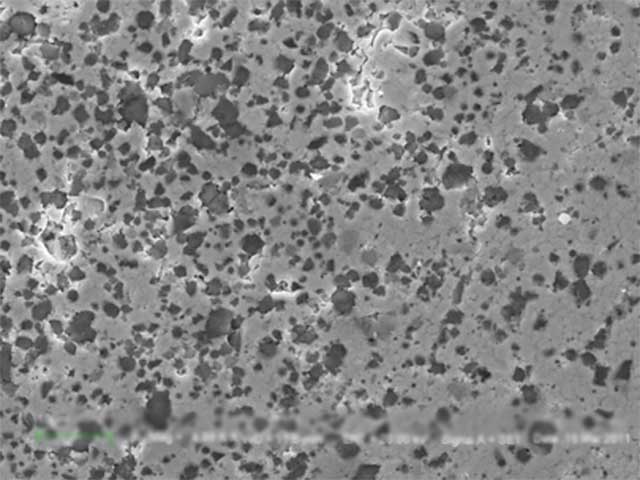

Which formulation of coolant with which additives is required and how can these be analysed and monitored? - Consultations and advice regarding the quality of your filter system.

Which filters are necessary in order to achieve the specifications for your products? - Support through generating a concept for system quality including for health and safety aspects within the workplace.

- Support in meeting the legislative requirements as well as identifying system improvements on top of those requirements. This includes generating risk assessments and operating instructions and the analysis required to create these.

- - Consultation regarding legally required and proactive systems and safety in production and waste disposal:

Are coolants compatible with elastomer system production and waste water?

How and where should the fluids be disposed of?

Cleaning of parts and surface protection

Consulting and support for all planning and optimisation work in all processes before, during and after cleaning parts.

- Consultation regarding the requirements for surface cleanliness with temporary corrosion protection.

- Which technologies have to be considered within the production systems for the parts?

- Consultation and generation of chemical/-physical concepts for all processes involving fluids and filters.

- Consultation for cleaning facilities and technologies, process monitoring with respect to technical cleanliness.

Which Filters are necessary for your requirements and production system? - Generating a concept for system quality including health and safety issues.

- Consultation regarding legal requirements and proactive safety systems in production and waste disposal:

Are coolants compatible with elastomer system production and waste water?

How and where should the fluids be disposed of?

Your advantage:

You will receive an independent, competent consultation with sustainable solutions being proposed.

For implementation in your Process-Quality Management the following are recommended Database and software [optiKSS] from ISOware GmbH

Coolants and lubricants

Cleaning of parts and surface protection